Fiberglass Specialties, Inc. started out in a small shop in 1992 producing around 500 parts a year and has now grown to producing over 12,000 parts annually. Our order driven process has earned us a reputation that is unsurpassable in the industry and we are continuing to raise the bar in precision and quality. Now with over 15,000 square feet to dedicate to our customers needs we can provide many different types of fiberglass processes and also carry many at one time.

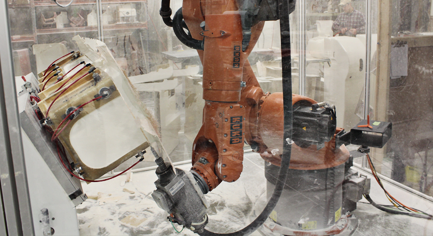

Fiberglass Specialties has the abilities to provide RTM (Resin Transfer Molding) and LRTM (Light Transfer Molding) close mold processes as well as Spray Up and Lay Up open mold.

We are also able to provide Injection Molding using various polymers to sustain proper durability for each job. Injection mold is a fast way to turn around complex parts.

Our versatile abilities in many different composite processes allows us to tailor to many different industries which include: Auto body parts, utility truck parts, fiberglass repair, custom parts for both manufactures and consumers all with the same quality and turn around time.